Dimensions / Weight

| W | H | D | |

|---|---|---|---|

| Dimensions | 214 mm (8.43 inch) | 81 mm (3.19 inch) | 340 mm (13.39 inch) |

PID Insulation Tester

TOS7210S

TOS7210S

360,000円 (税込:396,000円)

- Capable of setting within the range of 50Vdc to 2000Vdc (resolution 1V)

- Ability to switch the applied voltage polarity instantly by the switch on the front panel

- The output is floating from the ground potential.

- Capable of measuring the current value between measurement points.

This product generates high voltage! The use of this product requires knowledge of electricity.Improper handling or operation of this product can be very dangerous, so be sure to read the instruction manual carefully and use this product properly.

*Discontinued and only available while supplies last

Overview

The PID insulation tester (TOS7210S) is designed based on the insulation resistance tester (TOS7200) to carry out the evaluation of the PID (Potential Induced Degradation) effect of the PV module precisely and efficiently. Being equipped with the output ability of 2000V and the ammeter with nA resolution as well as a polarity switching function, the TOS7210S is also applicable not only to the PID evaluation but also the evaluation of the insulators that requires a high sensitivity of measurement. The tester is equipped with the panel memory that is externally accessible and RS232C interface as standard; it can be flexibly compatible with the automated system.

PID effect

The PID effect is a phenomenon that the amount of power generation by a cell remarkably decreases when high voltage is applied between the solar cell and the frame for long hours. It is supposed that the higher the applied voltage is and/or the higher and more humid the environment is, the further deterioration accelerates. For example, the potential difference in the string becomes extremely higher when the number of sheets that are connected in series increases even if the output voltage of the crystalline silicon solar cell module is just tens of volts. On the other hand, the grounding methods of the PCS (Power Conditioning System) that connects to the system as an AC power supply varies according to the type of PCS. In recent years, the transformerless method, where the input side is in the floating method (the negative polarity is not connected to the ground) is increasing. In this case, a high potential difference occurs between the cell and the ground. Regarding the crystalline silicon solar cell module, it is proved that the cell having a higher negative electric potential than that of the frame (ground) easily causes the PID effect. (See Fig. 1) The PV modules are currently managed with the maximum system of voltage as 600V in Japan and 1000V in Europe. There is a market trend that the maximum voltage of the commercial mega solar system is raised from the perspective of reducing the number of the strings and the total number of the PCS, and improving the efficiency of power generation.

![PID effect [Fig. 1]](https://kikusuiamerica.com/kiku/wp-content/uploads/2024/11/TOS7210S-fig03-en.jpg)

![PID effect [Fig. 2]](https://kikusuiamerica.com/kiku/wp-content/uploads/2024/11/TOS7210S-fig04-en-1.jpg)

Figure 2 shows the simulation of a crystalline silicon solar cell module being exposed to a high potential difference. It is considered that, in the PID effect of the crystalline silicon solar cell module, the sodium ion in the white tempered plate glass moves to the side of the cell and then causes the deterioration. (The PID ef fec t of the thin f ilm solar cell module is also confirmed, however, the mechanism of the deterioration is different from that of the crystalline silicon solar cell module.) The cause of the PID effect is currently being tested with and researched by various research organizations.

Capable of arbitrary setting of the output voltage

You can set the test voltage that is applied to the DUT within the range of 50 Vdc to 2000 Vdc (resolution 1V). In addition, an insulation resistance test of the electricity/electronic components or the electricity/electronic devices is also possible besides the voltage specified in JIS C 1302:1994. In the range of 50V to 1000V, the output properties are complied to JIS C 1302:1994.

Polarity switching function

You can easily change the output polarity by the switch on the front panel. The PID deterioration is a reversible phenomenon that may recover after the reverse bias voltage is applied. The polarity switching is a convenient function that can avoid a wiring change that connects to the DUT. In addition, switching by the external control through the RS232C interface is also possible.

Analog output terminal

In the resistance display mode, the voltage depending on the measured resistance is logarithmically compressed and output within the range of 0V to 4V. In the current display mode, the current is output in a linear scale depending on the measured current and ranges of measurement (4 ranges). You can analyze the changes or the deterioration status of the DUT by using an external recording device such as the data logger.

The output is floating from the ground.

The output terminal is floating from the ground electric potential. *1 In addition, a shield cable is adopted as an output cable. Therefore, it can be measured only an electric current flowing between test points excluding the one between the DUT and the ground, and it realizes to conduct the highly-sensitiveand precise evaluation.

*1: Ground voltage of the terminal that polarity is set as an anode (±1000 Vdc) Ground voltage of the terminal that polarity is set as a cathode (+1000 Vdc and -3000 Vdc)

Information related to PID test

Test on the PID effect

The experiment to reproduce the PID effect was conducted as the collaborative research theme in “Stage II Consortium of high-reliability PV module development and evaluation” that was established in April 2011 by the Research Center of Photovoltaic Technologies, National Institute of Advanced Industrial Science and Technology (hereinafter called “AIST”). Kikusui Electronics Corp. developed TOS7210S as a necessary test equipment contributed for this experiment project. *The contents mentioned above was announced in the 61st academic lecture of Japan Society of Applied Physics on March 19, 2014.

Creation of the single cell module

The 6-inch polycrystalline silicon cell of the test module is laminated, as a unit cell module, with white tempered glass, ethylene vinyl acetate (sealing material), and back sheet.

Materials used for a solar battery module

- Cell substrate: 6-inch polycrystalline silicon cell

- Light-receiving glass: White tempered glass

- Sealing material: Ethylene vinyl acetate (EVA)

- Back sheet: PVF/PET/PVF constituted back sheet

Test method

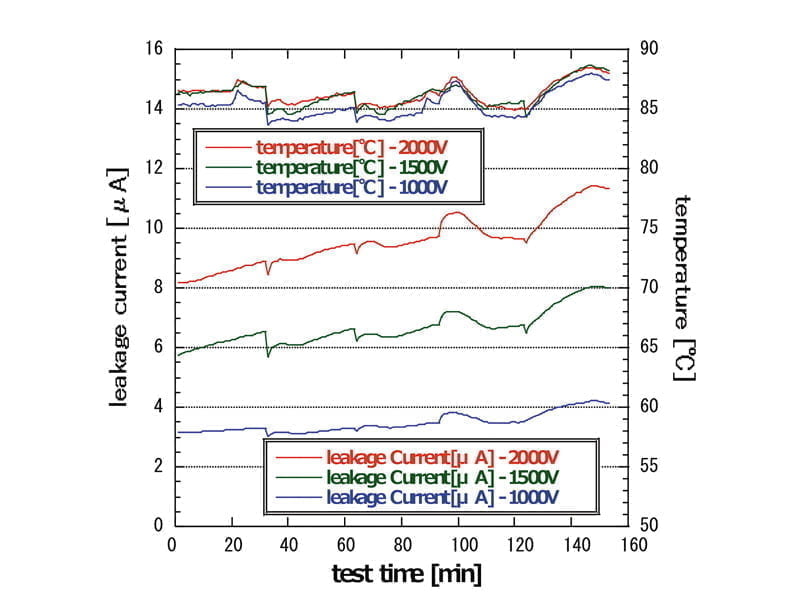

We installed the light receiving surface of the glass covered with an aluminum board in a constant temperature chamber and connected it to the PID insulation tester TOS7210S.

We then kept the module temperature at 85°C and applied -1000 Vdc, -1500 Vdc, and -2000 Vdc to each of three pieces of the single cell modules.

Confirmation of the output characteristics by the solar simulator

An output drop can be confirmed with the initial (Pmax/F.F./Isc/Voc) characteristics of the module and the changes with the elapsed time.

Confirmation of the deterioration by EL (electro-luminescence)

The normal par t emits light per fectly, but as the deterioration accelerates, the shaded area increases eventually and ceases to emit light. This method is adopted useful to confirm the PID effect. In addition, it is admitted that the deterioration in the PID effect is reduced with the elapled time by a reversible effect or recovered nearly to the initial state.

Confirm the difference in deterioration by applied voltage

The ratio that the maximum electricity (Pmax) of the module decreases when the applied voltage increases. In addition, as the EL image indicates, the higher the applied voltage becomes, the shaded area in the EL image increases in the same interval.

Recovery examination and the results by applying the reverse voltage

In the PID effect after conducting the reversible effect test, it may be found that the deterioration is reduced or rec over nearly to the initial state in some module by being lef t or t he rever se volt age is being applied. The polarity can be easily changed in TOS7210S with the switch. You are not bothered by the complicated connection to the DUT. The module that the Pmax drops remarkably (less than -99 %), and the recovery is not confirmed even after applying voltage for long hours. On the other hand, the module that the Pmax drops moderately (approximately -53 % to -71 %) recovered almost perfectly in 0.5 to two hours. In addition, it canbe recovered regardless of the applied voltage.

Various evaluation methods

Under the present conditions, any of the evaluation test method or the standard are not established. Each of the research organizations, experiment stations, and module manufacturers in the various countries conducting its own evaluation.

- Water method : Method to apply the water on the module glass surface and apply the voltage

- Chamber method : Method to manage temperature and humidity in the temperature chamber and apply the voltage

- Aluminum method : Method to cover the glass with an aluminum foil or let an aluminum board adhere to the glass surface, and apply the voltage

We continue experiments in each test method to examine each superiority and inferiority, difference by the temperature or humidity for future standardization. The international standard IEC is devising the test method for the PID effect.

Specifications

Output

| Output voltage | Range | 50 V to 2000 V |

|---|---|---|

| Resolution | 1V | |

| Accuracy | ± (1.5 % of setting + 2 V) | |

| Maximum rated output | 2 W (2000 V/1 mA) | |

| Max. rated current | 1mA | |

| Output terminal | Output form | Floating |

| Isolation voltage | ± 1000 Vdc (The terminal that polarity is set to positive polarity) + 1000 Vdc and -3000 Vdc (The terminal that polarity is set to negative polarity) | |

| Ripple | 2000 V/under no load | 20 Vp-p or less |

| Max. rated load | 20 Vp-p or less | |

| Voltage regulation | 1 % or less (maximum rated load → no load) | |

| Short-circuit current | 2 mA or less (250 mA or less instantaneous) | |

| Output rise time | 60 ms or less (10 % to 90 %, no load) | |

| Discharge function | Forced discharge at the end of test (discharge resistance: 20 kΩ) | |

Voltmeter

| Measurement range | 0 V to 2400 V | |

|---|---|---|

| Resolution | 1V | |

| Accuracy | ± (1 % of reading +1 V) | |

Resistance meter

| Measurement range | 0.01 MΩ to 5000 MΩ (In the range of over 100 nA to a maximum rated current of 1 mA) | |

|---|---|---|

| Display | □.□□MΩ [R<10 .0MΩ] □□.□MΩ [10 .0MΩ≦R<100.0MΩ] □□□MΩ [100 .0MΩ≦R<1000MΩ] □□□□MΩ [1000MΩ≦R≦5000MΩ] (R = measured insulation resistance) | |

| Accuracy *1 | ±(10% of reading) [100nA<i≦200nA] | |

| ±(5% of reading) [200nA<i≦1μA] | ||

| ±(2% of reading) [1μA<i≦1mA] | ||

| ( i= measured output-voltage value/measured resistance value) | ||

| Measurement range | The current measurement range is selectable between AUTO and FIX. | |

| AUTO | Automatically changes the current measurement range according to the measured current value. | |

| FIX | Fixes the current measurement range based on the output voltage set value and LOWER set value (in UPPER OFF status). | |

| Hold function | Holds the resistance value obtained at the end of testing while a PASS judgment is being output. | |

Ammeter

| Measurement range | 0.000 μA to 1900 μA | |

|---|---|---|

| Display | □.□□□μA [i<10 .00μA] □□.□□μA [10 .00μA≦i<100.0μA] □□□.□μA [100 .0μA≦i<1000μA] □□□□μA [1000μA≦i] ( i= measured current value) | |

| Accuracy*2 | ±(4% of reading +0.005μA) [i<10 .00μA] ±(4% of reading +0.005μA) [10 .00μA≦i<100.0μA] ±(2% of reading +0.005μA) [100 .0μA≦i<1000μA] (2% of reading) [1000μA≦i] ( i= measured current value) | |

| Measurement range | The current measurement range is selectable between AUTO and FIX. | |

| AUTO | Automatically changes the current measurement range according to the measured current value. | |

| FIX | Fixes the current measurement range based on the output voltage set value and LOWER set value (in UPPER OFF status). | |

Judgment feature

| Judgement method/action | LOWER FAIL Judgement | If a resistance value equal or less than the lower resistance is detected, the tester shuts off the output and returns a LOWER FAIL judgment. |

|---|---|---|

| W COMP Judgement | 上限基準値以上または下限基準値以下の抵抗値を検出した場合に出力を遮断しUPPERもしくはLOWER FAILと判定するウィンドコンパレート判定 |

Time

| Setting range for the test duration | 0.5 s to 999 s (TIMER OFF function provided) | |

|---|---|---|

| Setting range for the wait time | 0.3 s to 10 s (TEST TIME > WAIT TIME) | |

| Accuracy | ±(100 ppm + 20 ms) | |

*1: Humidity: 20 %rh to 70 %rh (no condensation). No bends in the test leads. *2: Humidity: 20 %rh to 80 %rh (no condensation). No bends in the test leads. Humidity 20 %rh to 70 %rh when either of terminal A or terminal B is grounded (no condensation). No bends in the test leads.

| SIGNAL I/O | D-SUB 25-pin connector on the rear panel | |||

|---|---|---|---|---|

| Input specifications | High-level input voltage | 11 V to 15 V | All input signals are active Low controlled. The input terminal is pulled up to +12 V using a resistor. Opening the input terminal is equivalent to inputting a high-level signal. | |

| Low-level input voltage | 0 V to 4 V | |||

| Low-level input current | -5 mA maximum | |||

| Input time width | 5 ms minimum | |||

| Output specifications | Output method | Open collector output (4.5 Vdc to 30 Vdc) | ||

| Output withstanding voltage | 30 Vdc | |||

| Output saturation voltage | Approx. 1.1 V (at 25°C) | |||

| Maximum output current | 400 mA (TOTAL) | |||

| ANALOG OUT | Outputs the measured resistance, measured current and voltage, and current range in DC voltage. | |||

| Measured resistance |  Rx: (1 MΩ: 0.3 V, 10 MΩ: 1.04 V, 100 MΩ: 2.00 V, 1000 MΩ: 3.00 V, 10000 MΩ or more: 4.00 V) Output impedance: 1 kΩ | |||

| Measured current | Renge1: V 0 [V]= measured value [μA]/ 512 Renge2: V 0 [V]= measured value [μA]/64 Renge3: V 0 [V]= measured value [μA]/8 Renge4: V 0 [V]= measured value [μA] | |||

| COM | Analog output-circuit common | |||

| Accuracy | ±(2 % of full scale) | |||

| RS232C | D-SUB 9-pin connector on the rear panel (compliant with EIA-232-D) All functions other than the POWER switch and KEYLOCK function are remotely controllable | |||

| Baud rate | 9600 bps/19200 bps/38400 bps (data: 8 bits; parity: none; stop bit: 2 bits fixed) | |||

| REMOTE | 6-pin mini-DIN connector on the front panel. The optional remote controller RC01-TOS or RC02-TOS is connected to control remotely starting/stopping of a test (note that a DIN-mini DIN adapter is required). | |||

| Display | 7-segment LED, 4-digit voltage display, 4-digit insulation resistance display, 4-digit current display, and 3-digit time display | |||

| Memory function | A maximum of 10 types of test conditions can be stored in memory | |||

| TEST MODE | MOMENTARY | A test is conducted only when the START switch is pressed. | ||

| FAIL MODE | Disables cancellation of FAIL judgment using a stop signal via remote control. | |||

| DOUBLE ACTION | Starts a test only when the STOP switch is pressed and the START switch is pressed within approximately a half-second. | |||

| PASS HOLD | Allows the time of holding PASS judgment to be set to 0.2 s or HOLD | |||

| KEYLOCK | Places the tester in a state in which no keystroke other than the START/STOP switch is accepted | |||

| Environment | Installation location | Indoors, 2000 m or less | ||

| Spec guaranteed range | Temperature/Humidity | 15 °C to 30 °C (59 °F to 86 °F )/ 20 % rh to 80 % rh (no condensation) | ||

| Operating range | Temperature/Humidity | 0 °C to 40 °C (32 °F to 104 °F )/ 20 % rh to 80 % rh (no condensation) | ||

| Storage range | Temperature/Humidity | -20 °C to 70 °C (-4 °F to 158 °F )/ 90 % rh or less (no condensation) | ||

| Power supply | Nominal voltage range(allowable voltage range) | 100 Vac to 240 Vac (85 Vac to 250 Vac) | ||

| Power consumption | Rated load | 30 VA maximum | ||

| Allowable frequency range | 47 Hz to 63 Hz | |||

| Insulation resistance | 30 MΩ or more (500 Vdc) (AC LINE to chassis) | |||

| Withstanding voltage | 1500 Vac for 1 second, 10 mA or less (AC LINE to chassis), 3000 V AC for 1 second (A, B terminals to chassis) | |||

| Ground bond | 25 Aac/0.1 Ω or less | |||

| Dimensions (mm (inch)) (maximum dimensions) / Weight | 214 (8.43″) W × 81(3.19″) (115 (4.53″)) H × 340 (13.39″) (385 (15.16″)) D/ Approx. 2 kg (Approx.4.41 lbs) | |||